Tel:+86 535 6311168

Tel:+86 13723968600

Fax:+86 535 6311168

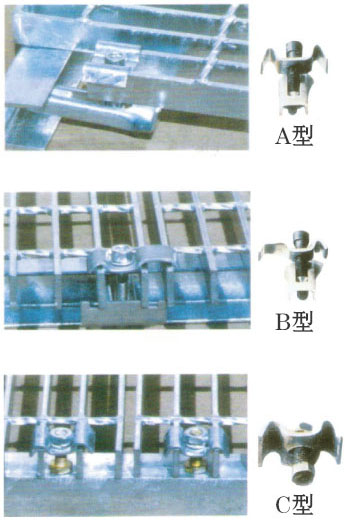

For installation, two fastening methods can be used ,welding or using saddle clips. For permanent and non-removed Installations, the steel gratings are tack-welded to supporting steel. As for the location for welding please see the scheme below. At the four corners of panel, the first bearing bar is tack-welded to the support member with 3mm min fillet weld ×20mm min long.Senior saddle clips, which have such advantages as not destroying zinc coat and easy removing,are available. Each panel shall use at least four saddle clips.For the larger panels preferably a few more clips are used to fix to the available support members. When selecting saddle clips,please refer to themllowinct table.

Type A-comprising a top clip with double saddle, a lower clip with teeth and a M10(or MB) inner-hexagon-circular-stud bolt.

Type B-comprising a top clip with double saddls,(of which one saddle can secure the two bearing bars of adjacent panels), alower clip with teeth and a M10(or MB)inner-circular-stud-bolt.

Type C-comprising a top clilp with double saddle and a M10(or M8) hexagon-heeded bolt which can be welded to the support member.

installation clips type selection

Prex:no more

Next:no more